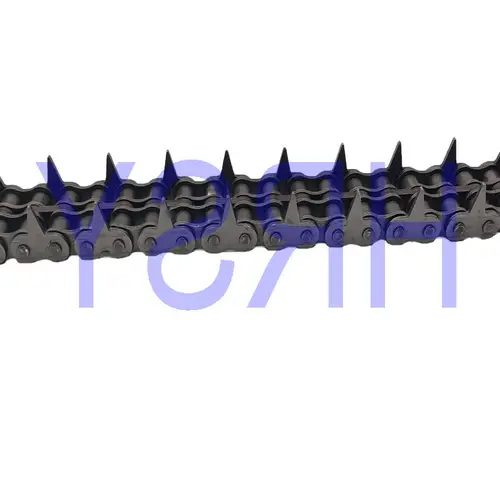

China Good quality OEM Customized Top Sharp Tooth Transmission Chain Coupling for Conveyor supplier

Product Description

Stainless Steel Chains

Stainless steel chains are widely used in various industries such as food processing, pharmaceuticals, chemicals, rubber processing, and non-ferrous metal smelting. These chains are essential for mechanical transmission and conveying equipment. They offer high strength, wear resistance, and corrosion resistance, making them ideal for demanding applications.

Traction Chains

Traction chains find extensive use in equipment like forklifts, stackers, textile machinery, drilling rigs, and more. These chains provide reliable driving and conveying functions, ensuring efficient operations in various industries.

Drive Chains

Drive chains are primarily used for power transmission and are widely utilized in agricultural machinery, construction machinery, escalator drives, and packaging machinery industries. These chains are known for their high wear resistance, fatigue strength, and precision.

Conveyor Chains

Conveyor chains play a crucial role in industries such as food, wood and paper, logistics, packaging machinery, and building materials. They ensure smooth and reliable material conveying, offering features like high strength, wear resistance, and temperature resistance.

Details Images

Agricultural Machinery Chain

Agricultural machinery chains are specifically designed for use in rice, wheat, corn, cotton, and other agricultural machinery. They provide driving and conveying functions, facilitating the mechanization of the entire agricultural production process from plowing to harvesting.

Conveyor Chain

Conveyor chain products are characterized by their high strength, wear resistance, precision, and corrosion resistance. These chains are designed to meet the requirements of efficient, smooth, and reliable conveying in various industries.

Drive Chains

Our transmission chains are manufactured using high-quality materials and advanced technology, resulting in high-end chain transmission products. These chains offer exceptional wear resistance, fatigue strength, and precision, making them ideal for various applications.

Product Parameters

(Insert product parameters here)

Frequently Asked Questions (FAQs)

Q1: What industries can benefit from stainless steel chains?

Stainless steel chains are widely used in food processing, pharmaceuticals, chemicals, and many other industries that require high-quality, corrosion-resistant chains for their mechanical transmission and conveying equipment.

Q2: How do traction chains contribute to efficient operations in forklifts and stackers?

Traction chains provide reliable driving and conveying functions in forklifts and stackers, ensuring smooth movement of materials and efficient operations in warehouses, logistics centers, and other industrial environments.

Q3: What makes drive chains suitable for agricultural machinery?

Drive chains are specifically designed to transmit power in agricultural machinery. They offer high wear resistance, fatigue strength, and precision, enabling the mechanization of various agricultural processes, including plowing, sowing, and harvesting.

Q4: How do conveyor chains enhance material conveying in different industries?

Conveyor chains are widely used in food, wood and paper, logistics, packaging machinery, and building material industries to efficiently and reliably convey materials. These chains provide high strength, wear resistance, and temperature resistance, ensuring smooth operations in material handling.

Q5: What are the advantages of our transmission chains?

Our transmission chains are made of high-quality materials using advanced technology. These chains offer exceptional wear resistance, fatigue strength, and precision, providing reliable power transmission solutions in agricultural machinery, construction machinery, and other industries.

About Our Company

Our company is a leading supplier of various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, sharp top chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to offering high-quality products, competitive prices, and excellent customer service.

With over X years of experience, we have established ourselves as a trusted brand in the industry. Our products are widely used in logistics and conveying, food industry, petroleum industry, engineering machinery, and other fields. We welcome customers to customize products based on their specific requirements, providing tailored solutions to meet their needs.

(Insert any additional promotional content about the company’s products, such as highlighting high-quality products, preferential prices, and considerate services.)

All content on this page is from the Internet. It is intended only as a reference for product selection. Our products are replacement parts, not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Performance Characteristics of Sharp Top Chain

The Sharp top chain is a type of roller chain that features a unique tooth design that increases its strength and durability. When compared to standard roller chains, Sharp top chains have several performance characteristics that make them more suitable for certain applications.

High Strength: Sharp top chains are designed to have a higher tensile strength than standard roller chains. This makes them more resistant to wear and tear, and better able to withstand heavy loads.

Increased Durability: The unique tooth design of Sharp top chains reduces the wear and tear on the chain, increasing its lifespan and reducing the need for maintenance.

Reduced Noise: Sharp top chains operate more quietly than standard roller chains, making them ideal for applications where noise levels need to be kept to a minimum.

Smooth Operation: The design of Sharp top chains ensures that they operate smoothly, even under heavy loads. This is due to the reduced friction between the chain and sprocket teeth, which reduces the amount of heat generated during operation.

Types and Characteristics of Sharp Top Chain

There are several types of Sharp top chains available, each with its own unique characteristics.

Standard Sharp Top Chain: This is the most common type of Sharp top chain. It features a standard pitch and tooth profile, and is suitable for a wide range of applications.

Heavy Duty Sharp Top Chain: This type of Sharp top chain is designed for heavy-duty applications, such as in the wood processing and recycling industries. It features a larger pitch and tooth profile, as well as thicker side plates for increased strength.

Oilfield Chain: This type of Sharp top chain is designed for use in the oil and gas industry, where it is exposed to harsh environmental conditions. It features a special coating that resists corrosion and other forms of damage.

Advantages of Sharp Top Chain Made of Different Materials

Sharp top chains can be made from a variety of materials, each with its own advantages.

Stainless Steel: Stainless steel Sharp top chains are highly resistant to corrosion, making them ideal for use in harsh environments.

Carbon Steel: Carbon steel Sharp top chains are strong and durable, making them ideal for heavy-duty applications.

Plastic: Plastic Sharp top chains are lightweight and resistant to corrosion, making them ideal for use in applications where weight is a concern.

Applications of Sharp Top Chain

Sharp top chains are used in a variety of industries, including the Wood Processing Industry, Recycling Industry, Agricultural Industry, Automotive Industry, and Textile Industry.

Wood Processing Industry: Sharp top chains are used in sawmills and other wood processing facilities to transport logs and lumber.

Recycling Industry: Sharp top chains are used in recycling facilities to transport and sort recyclable materials.

Agricultural Industry: Sharp top chains are used in farming equipment, such as combines and feeders.

Automotive Industry: Sharp top chains are used in automotive manufacturing, such as in conveyor systems and assembly lines.

Textile Industry: Sharp top chains are used in textile manufacturing, such as in spinning frames and weaving machines.

Future Development Trends and Opportunities

The future of Sharp top chain products looks bright, with a number of opportunities for growth and development. Some of the trends that are likely to shape the industry include increased automation, the use of advanced materials, and a focus on sustainability.

How to Choose a Suitable Sharp Top Chain

Choosing the right Sharp top chain for your application requires careful consideration of several factors.

Determine Application Requirements: Consider the load capacity, speed requirements, and environmental factors of your application.

Identify the Type of Chain: Choose the type of Sharp top chain that is best suited for your application.

Select the Chain Material: Choose the material that is best suited for your application, based on factors such as corrosion resistance, strength, and weight.

Consider the Chain Dimensions: Choose the chain dimensions that are suitable for your application, based on the load capacity and speed requirements.

Check Compatibility with Sprockets: Make sure that the Sharp top chain you choose is compatible with your existing sprockets.

Conclusion

Sharp top chains are a vital component of many industrial applications, offering high strength, durability, and reduced noise. By choosing the right type of Sharp top chain for your application, you can ensure maximum performance and longevity.

Author: Dream